What should we pay attention to when filming aluminum products?

- By:Naview

- Date:2022-04-25

1. The aluminium profile should not be placed for too long after the anodizing treatment. It is best to apply the film immediately to prevent dust from falling on the surface of the profile and affecting the quality of the film.

2. The width of the film should be the same as the width of the profile surface or slightly larger than the width of the film surface of the aluminium profile. If the width of the film is too wide, it will lead to a loose fit and warped edges, and if it is too narrow, it will not cover the entire surface of the profile.

3. The film cannot form excessive tension, that is, the film cannot be deformed, otherwise it is easy to cause the film to shrink, resulting in no film coverage at both ends of the aluminium profile.

4. When the veneer boundary is located at the edge of the groove of the aluminum profile, such as the photovoltaic frame aluminium profile, the burrs of the film should be pressed into the groove. The film should be pasted flat to prevent warping.

5. For some thin-walled or large cantilevered aluminium profiles, it is not advisable to press too tightly to prevent the profiles from deforming.

6. For some complex cross-section aluminium profiles, it is difficult to paste a layer of film. You can try multi-layer paste to ensure coverage.

7. The choice of the film is also very important. The viscosity of the film is too large, which will make it difficult to tear the film later. The viscosity of the film is not enough and it is easy to fall off the profile.

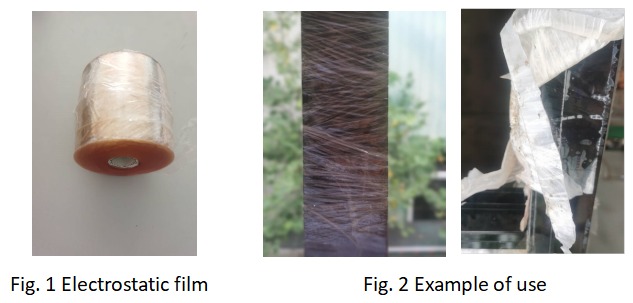

Note:The PVC electrostatic film currently on the market (commonly known as the stretch film as shown in Figure 1) is not suitable for aluminum materials. It has strong elasticity and a pungent odor. After irradiation, strong corrosive substances will be precipitated to corrode the surface film of the aluminum material. After the film is corroded, it cannot be recovered (as shown in Figure 2), which will lead to huge economic losses. Our company now reminds you not to use it.

The PVC electrostatic film currently on the market (commonly known as the stretch film as shown in Figure 1) is not suitable for aluminum materials. It has strong elasticity and a pungent odor. After irradiation, strong corrosive substances will be precipitated to corrode the surface film of the aluminum material. After the film is corroded, it cannot be recovered (as shown in Figure 2), which will lead to huge economic losses. Our company now reminds you not to use it.

CONTACT US

Foshan Naview New Building Materials Co., Ltd.

We are always here offering customers our reliable products and service.

If you want to liaise with us now, please click contact us