What are the conditions for customization of aluminum alloy profiles?

- By:Naview

- Date:2024-02-23

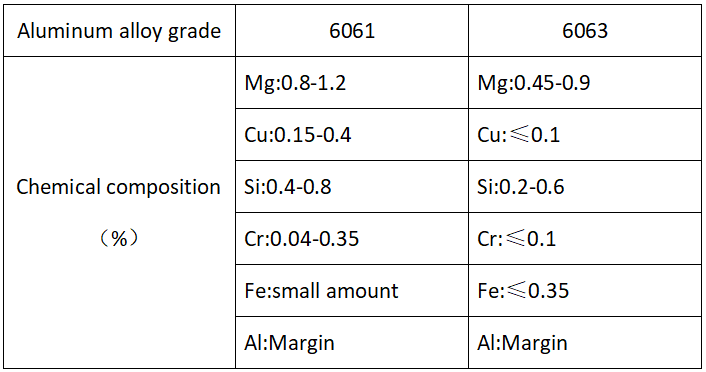

Aluminum extrusions are lightweight, durable, and versatile, and are the most widely used non-ferrous metal material with an ever-expanding range of applications. However, given the numerous aluminum profile models in the market, two of the most common aluminum profile materials are 6061 and 6063. 6061 Aluminum Alloy is designed to resist corrosion and is easy to weld. Its higher strength makes it suitable for applications that require higher strength and durability, such as aerospace, sports equipment, automotive parts, etc. 6063 aluminum alloy has good formability and corrosion resistance, and is easy to cut and weld. Its surface can be anodized to enhance its durability and aesthetics. It is suitable for furniture, construction, decoration and other fields. Custom molding of aluminum profiles is a professional service that creates unique aluminum parts based on customers’ needs. Through custom mold opening, customers can obtain aluminum profiles that meet their specific requirements, allowing for personalized design and functionality. There are many advantages of custom mold opening for aluminum profiles, including flexibility, precision and high quality.

For one thing, custom mold opening for aluminum profiles can meet customers’ individual needs. Each customer has different needs and requirements, which may not be fully met by using existing aluminum profiles to meet their design and functional requirements. Through custom molding, unique aluminum profiles can be made according to the design drawings and requirements provided by customers, thus realizing distinctive products. Secondly, custom molding of aluminum profiles has a high degree of accuracy. Custom mold opening can make aluminum profiles according to the precise dimensional requirements of customers, ensuring the accuracy and consistency of the products. Whether it is complex shapes or subtle details, custom molding can be accurately manufactured to ensure the quality and reliability of the product , Third, custom molding of aluminum profiles focuses on high quality manufacturing. In the process of custom mold opening, high-quality aluminum materials are selected and equipped with advanced equipment and processes to ensure that the quality of the products reaches the best level. Through strict quality control and inspection, as well as reasonable production process, Aluminum Profile Custom Open Die can produce high quality aluminum parts to meet customers’ high quality requirements.

Finally, customized open die for aluminum profiles has the advantages of quick response and short production cycle. With the continuous advancement of technology, the time and process of custom mold opening have been dramatically shortened. Customers can quickly obtain aluminum profiles that meet their needs, shorten product development and delivery time, and improve market competitiveness. Overall, custom molding of aluminum profiles is a service designed to meet the individual needs of customers. Through custom molding, it is possible to create one-of-a-kind aluminum parts that meet customers’ design and functional requirements. Whether it’s shape, size or quality, custom molding of aluminum profiles can provide flexible, precise and high-quality solutions to fulfill customers’ needs and expectations.

CONTACT US

Foshan Naview New Building Materials Co., Ltd.

We are always here offering customers our reliable products and service.

If you want to liaise with us now, please click contact us