Design Guidelines for Aluminium Profile Extrusion

- By:Naview

- Date:2022-01-17

The aluminium profile extrusion process produces profiles with lengths ranging from eight feet to twenty-four feet. The profiles can be heat treated, finished, or fabricated to meet customer specifications. The manufacturer should follow the guidelines provided in the Aluminium Extrusion Design Guide to ensure the best possible outcome. In the process of designing an extruded part, it is important to consider the following factors. The first consideration is the length.

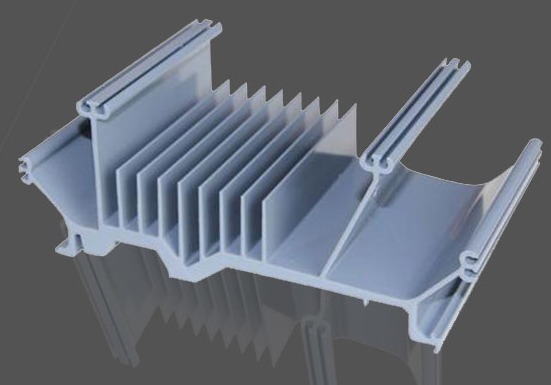

The next step in profile extrusion such as aluminium T slot profile is to determine the design shape. The process requires precision calculations. A good example of a design is an octagonal or angled cross section. A simple octagonal cross section will be ideal for most applications. If a more complex design is required, the aluminium extrusion process can be customized to meet the customer’s specifications. After the extrusion process, the aluminum profile can be cut, drilled, or punched for special purposes.

Once a product is ready for extrusion, it needs to be cooled. This process is known as cold hardening. The final product is fully formed after the material has been drawn. The extrusion process can also be customized to meet the customer’s specific requirements. For example, an aluminum profile may be made from multiple layers of aluminium. The thickness can be adjusted to meet the needs of the customer.

When designing an aluminium extruded profiles, it is important to consider the material and the intended use. A profile can be customised in several industries. Some of these include packaging, construction, and furniture. The aluminium profile extrusion process allows for the creation of aluminium profiles of various shapes and sizes. Its use is limited only by its application. This type of product can be made to fit the needs of the end users.

The aluminium profile extrusion process is the process of moulding a profile. The process resembles the process of squeezing toothpaste. The billet is a heated aluminium block. The die is a tool that cuts the billet into the desired shape and size. The resulting aluminum profile is then drawn out of the tool. The final strength of an aluminium profile depends on the type of finish and the alloy.

CONTACT US

Foshan Naview New Building Materials Co., Ltd.

We are always here offering customers our reliable products and service.

If you want to liaise with us now, please click contact us