Aluminum T-Slot Profile Buying Guide: How to Identify and Select the Right Type for You?

- By:Naview

- Date:2025-11-12

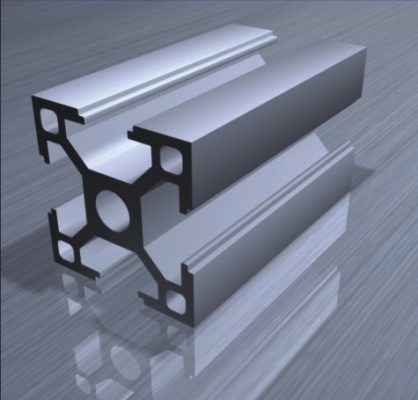

I. Understanding the Basic Classification of Aluminum Profiles

Aluminum profiles can be categorized by application into architectural aluminum profiles, industrial aluminum profiles, and decorative aluminum profiles. Architectural aluminum profiles are primarily used in structures such as doors, windows, and curtain walls, emphasizing strength and weather resistance. Industrial aluminum profiles are used for manufacturing frames, brackets, and similar components, prioritizing load-bearing capacity and precision. Decorative aluminum profiles focus more on appearance and design aesthetics.

II. Key Parameters for Identifying Aluminum Profiles

T-slot aluminum profiles come in numerous specifications, with common series including 20, 30, 40, 50, 60, and 80. Each series features distinct cross-sectional dimensions and load-bearing capacities. When selecting profiles, first determine the frame’s load requirements and choose the corresponding profile specification based on the load size. For instance: – Light-duty frames (up to 50kg load capacity) may use Series 20 or 30 profiles; – Medium-duty frames (50-200kg load capacity) suit Series 40 or 50 profiles; – Heavy-duty frames (over 200kg load capacity) require Series 60, 80, or larger profiles. Additionally, consider wall thickness—greater thickness enhances load-bearing capacity.

2. Focus on surface treatment processes to ensure corrosion resistance

Alloy Composition: Different aluminum alloy compositions determine profile properties. For instance, 6063 alloy is commonly used in construction, while 6061 alloy is more suitable for industrial applications.

Surface Treatment: Processes such as anodizing, electrophoretic coating, and powder coating affect the profile’s corrosion resistance and aesthetic appeal.

Dimensional Accuracy: Select appropriate tolerance grades based on usage requirements to ensure assembly compatibility and structural integrity.

Mechanical Properties: Including tensile strength and yield strength, these metrics directly impact the profile’s service life and safety.

3. Inspect Profile Precision and Straightness to Ensure Assembly Quality

Profile accuracy and straightness are critical factors affecting frame assembly quality and stability. During procurement, use calipers to measure sectional dimensional tolerances and employ straight edges or spirit levels to verify straightness. High-quality T-slot aluminum profiles should maintain sectional tolerances within ±0.1mm and straightness not exceeding 0.5mm per meter. Inadequate precision leads to lose connections, causing frame wobbling and deformation.

4. Choose good connectors to make sure your connections are strong.

Connectors are the “joints” of T-slot aluminium profile frames, and their quality directly affects how stable and safe the frame is. When buying, choose connectors that match the profile specifications, and pay attention to the material and how precise the machining is. Premium connectors are usually made from strong aluminium or stainless steel, with surfaces that are either galvanized or anodized to make them resistant to wear and corrosion. For example, special T-slot parts like hex socket bolts, T-nuts and corner brackets should have clear threads and a tight fit. This means they can handle enough tensile force and torque.

5. What you need to do to customize it.

If your project has special needs, such as different sizes or surface treatments, customization services can be very important. Let suppliers know exactly what you need so they can give you the right solution.

Ⅲ.Aluminum Industry T-Slot FAQ

Q1: What distinguishes T-slot aluminum profiles from standard aluminum profiles?

A1: The primary difference lies in the T-shaped groove design on the surface of T-slot aluminum profiles. This groove design allows T-slot profiles to integrate with specialized connectors for welding-free, rapid assembly. Standard profiles typically require welding or direct bolting, resulting in lower assembly flexibility and efficiency. Additionally, T-slot profiles are generally manufactured from higher-strength industrial aluminum alloys, offering superior performance for industrial framework construction. Standard profiles are more commonly used in non-load-bearing applications such as decoration, doors, and windows.

Q2: Does assembling T-slot aluminum industrial profiles require specialized technicians?

A2: No. T-slot aluminum industrial profiles utilize a modular assembly approach, making operation simple and convenient. Ordinary workers can master assembly techniques after minimal training. Common tools like hex keys and screwdrivers suffice during assembly, eliminating the need for welding equipment or specialized welding skills. Manufacturers typically provide detailed assembly drawings and manuals to guide users, significantly lowering technical requirements for operators.

Q3: What is the load-bearing capacity of T-slot aluminum frames? Can they support heavy equipment?

A3: The load-bearing capacity of T-slot aluminum frames depends on the profile specifications, wall thickness, connection methods, and overall frame structure. By selecting appropriate profile sizes and optimizing the frame design, T-slot aluminum frames can withstand substantial weights and are suitable for heavy equipment. For example, a frame constructed from 80-series T-slot aluminum profiles (3mm wall thickness) can achieve a single-point load capacity exceeding 500kg, fully meeting the frame requirements for most heavy industrial equipment. In practical applications, manufacturers provide professional frame design solutions based on clients’ load-bearing requirements to ensure structural safety.

Q4: What is the service life of T-slot aluminum industrial profiles?

A4: The service life of T-slot aluminum industrial profiles primarily depends on the usage environment and maintenance practices. In standard industrial settings, anodized T-slot aluminum profiles exhibit excellent corrosion and wear resistance, with a service life of 10–15 years. When used outdoors or in highly corrosive environments, employing advanced surface treatments (such as thickened anodized coatings or electrophoretic painting) can extend service life to 8–10 years. Additionally, T-slot aluminum frames can be repeatedly disassembled and reassembled, further extending material longevity.

Q5: Can T-slot aluminum industrial profiles undergo secondary processing?

A5: Yes. T-slot aluminum industrial profiles offer excellent machinability, allowing secondary processing like cutting, drilling, and milling grooves according to specific requirements. Cutting can be performed using specialized aluminum profile cutters for high precision and clean edges. Drilling and milling grooves can be completed with CNC machining equipment to ensure processing accuracy. Secondary processing enables T-slot aluminum industrial profiles to better adapt to complex installation scenarios and special structural requirements, enhancing product flexibility and applicability.

If you’re seeking efficient, high-quality, and cost-effective industrial framing materials, consider T-slot aluminum industrial profiles. Partner with a reliable T-slot aluminum supplier to access professional products and customized solutions. Let T-slot aluminum industrial profiles inject new momentum into your business development and usher in a new era of efficient industrial manufacturing! Contact us now to receive complimentary product samples and framing design proposals. We look forward to collaborating with you for mutual success!

CONTACT US

Foshan Naview New Building Materials Co., Ltd.

We are always here offering customers our reliable products and service.

If you want to liaise with us now, please click contact us