- Home » News » Product Information » Details About Aluminium Extruded Profiles In Processing

Details About Aluminium Extruded Profiles In Processing

- By:Naview

- Date:2021-12-22

The cost of aluminium extruded profiles is largely determined by the weight and metal content. It is therefore crucial to minimise the weight of your profile. The easiest way to do this is to design your profiles as light as possible, within the limitations of the extrusion process. This can be achieved by making walls thinner and removing unnecessary features. You can also use struts and hollows to reduce the mass of your profile and avoid the need for further machining.

There are many extrusion processes to choose from. Firstly, you should determine the exact profile that you need, as not all extruders offer these services. Some focus on simple pressing and bulk aluminium profiles, whereas others focus on complex shapes and tolerances of less than two millimetres. This will help you find the best one for your project. For instance, if you need a complex shape in thin walled profiles with +0.02mm tolerance, you can choose the T slot aluminium extrusion.

Generally Speaking, Using a profile that is made from aluminium is an excellent option for a variety of applications. Not only is it lightweight, but it is also corrosion resistant. In addition to its low price, Naview‘s aluminium extruded profiles are very affordable. In fact, the cost of making a typical aluminium extruded profile is approximately 1/3 that of steel. Furthermore, aluminium can be recycled, which means that the process only uses five percent of the energy that was used in making the original aluminum.

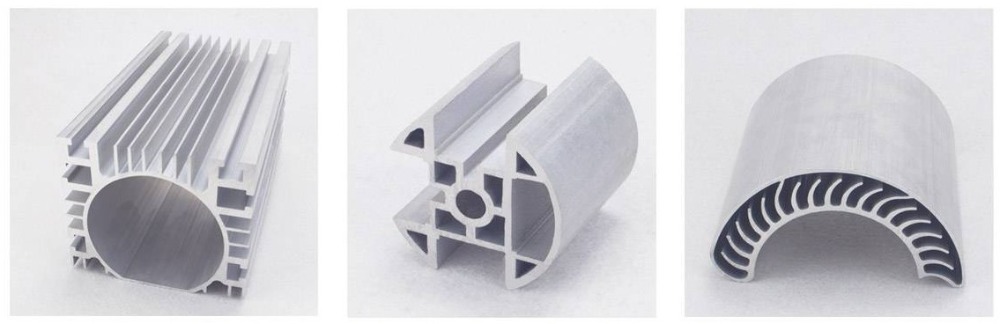

As we know that the aluminium extruded products can be produced in a variety of shapes. The most common shapes are round tubes, angles, channels, and channels. Some extruders also produce a variety of other alloys. They are generally subject to the standards EN 755-9 and EN 12020-2, which deal with form and dimensions tolerances. These standards are often required when producing aluminum extruded profiles. The process of extruding a profile may be a lengthy one, but is worth the effort to ensure the quality of the finished product.

Extrusion is a process for moulding aluminium. It is similar to squeezing toothpaste from a tube. The billet is heated to 450-500 degrees Celsius. The die is used to pull the aluminum out of the billet. Once the material is cooled, it can be easily shaped into whatever shape it is. If the profiles are too thin, they can be bent, or even welded.

Extruded aluminium profiles are available in a range of shapes and sizes. For example, you can find frames, channel, and round tubes. You can also find them in accessories, such as hinges, latches, and other fasteners. You can even make custom-made shapes. If you can’t find the type of product you need, you can have it customized . It’s worth a try.

CONTACT US

Foshan Naview New Building Materials Co., Ltd.

We are always here offering customers our reliable products and service.

If you want to liaise with us now, please click contact us